Pretzels – Bicarbonate Applications

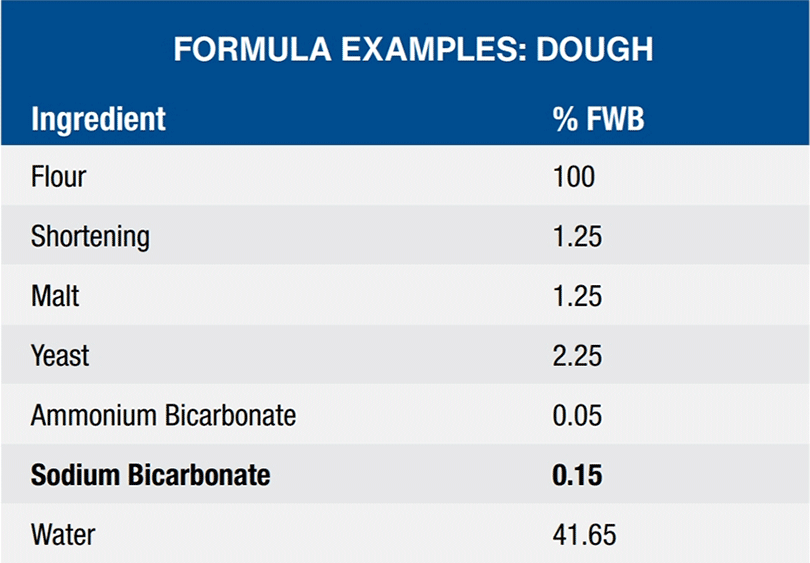

Pretzels are known for their characteristic taste, texture and appearance. Chemical leavening impacts all three characteristics. Sodium bicarbonate is found either in the pretzel dough or in the alkali solution used to dip the pretzels. Ammonium bicarbonate is also used in the pretzel dough to leaven without leaving any residue.

The production steps involved in the manufacturing of pretzels are mixing, fermenting, forming, proofing, cooking, baking and drying. Pretzel doughs are made to be very stiff so that they can withstand the rigors of machining without losing their shape or becoming sticky. The bicarbonates are used to provide an open cell structure within the pretzel.

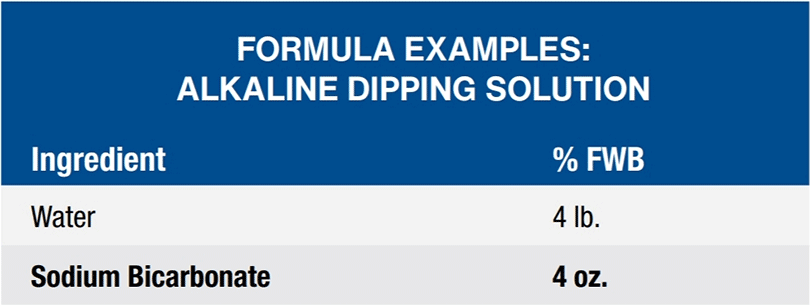

Of all the steps in the production of pretzels, cooking is the most important. The type of dipping alkali and the proper application of the alkaline cooking solution is the most critical to the taste and appearance of pretzels. An alkaline solution with a high pH will increase the surface browning and flavor contrast. During the bath exposure, natural sugars caramelize and the starch gelatinizes, creating the characteristic brown color and gloss in the finished product.

The dipping stage normally takes just 10-15 seconds of exposure to the hot alkaline solution which is about 200°F. Traditionally the solution was a mixture of sodium hydroxide and water. Today, most production involves the use of sodium carbonate and bicarbonate solutions which are not as caustic as NaOH. Because carbonates and bicarbonates are not as caustic as sodium hydroxide, they are safer to use both in handling and in equipment operation.

Bicarbonate Recommendation

Sodium Bicarbonate Grade 1 Powdered:

Dissolves rapidly to assure quick, complete availability for reaction with acid ingredients.

Sodium Bicarbonate Grade 1 TFF:

Treated with tricalcium phosphate to improve flow quality. Dissolves rapidly to assure quick, complete availability for reaction with the acid ingredients.

Sodium Bicarbonate Grade 2 Fine Granular:

The narrow particle size distribution of Grade 2 facilitates rapid uniform blending. This grade is recommended for those products where minimal leavening during mixing and holding is desired. It is also recommended for products where pre-reaction during preparation can be a problem. It is very useful in refrigerated and frozen doughs to limit pre-reaction with acid ingredients during storage.

Flow K™ Potassium Bicarbonate:

Potassium bicarbonate performs exceptionally well as a replacement for sodium bicarbonate in most chemically leavened products. For equivalent CO2 release, 20% more potassium bicarbonate must be used.

Ammonium Bicarbonate:

ABC reacts rapidly in the presence of moisture and/or heat to release CO2 and NH3 gases which contribute to leavening. Use of ABC without a leavening acid is limited to products whose final moisture is less than 5% so the ammonia gas can bake out.